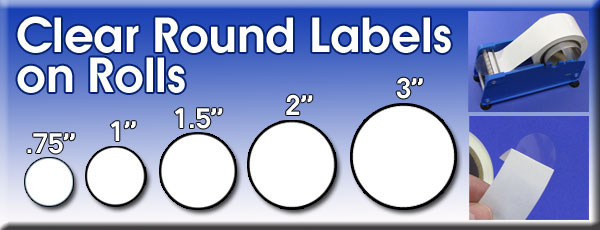

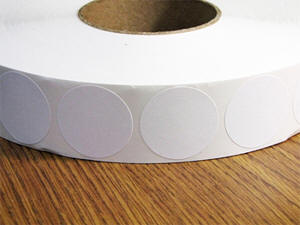

Clear Round Perforated Labels on Rolls

Click to go back to www.ClearRoundLabels.com

ProfessionalLabel.com stocks 2 sizes of clear round perforated label seals.

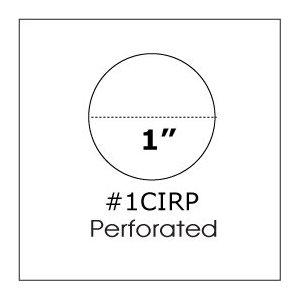

One inch clear round perforated labels

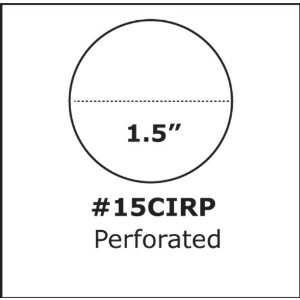

and One and a Half inch clear round labels.

All labels on rolls displayed on this site may be purchased online from

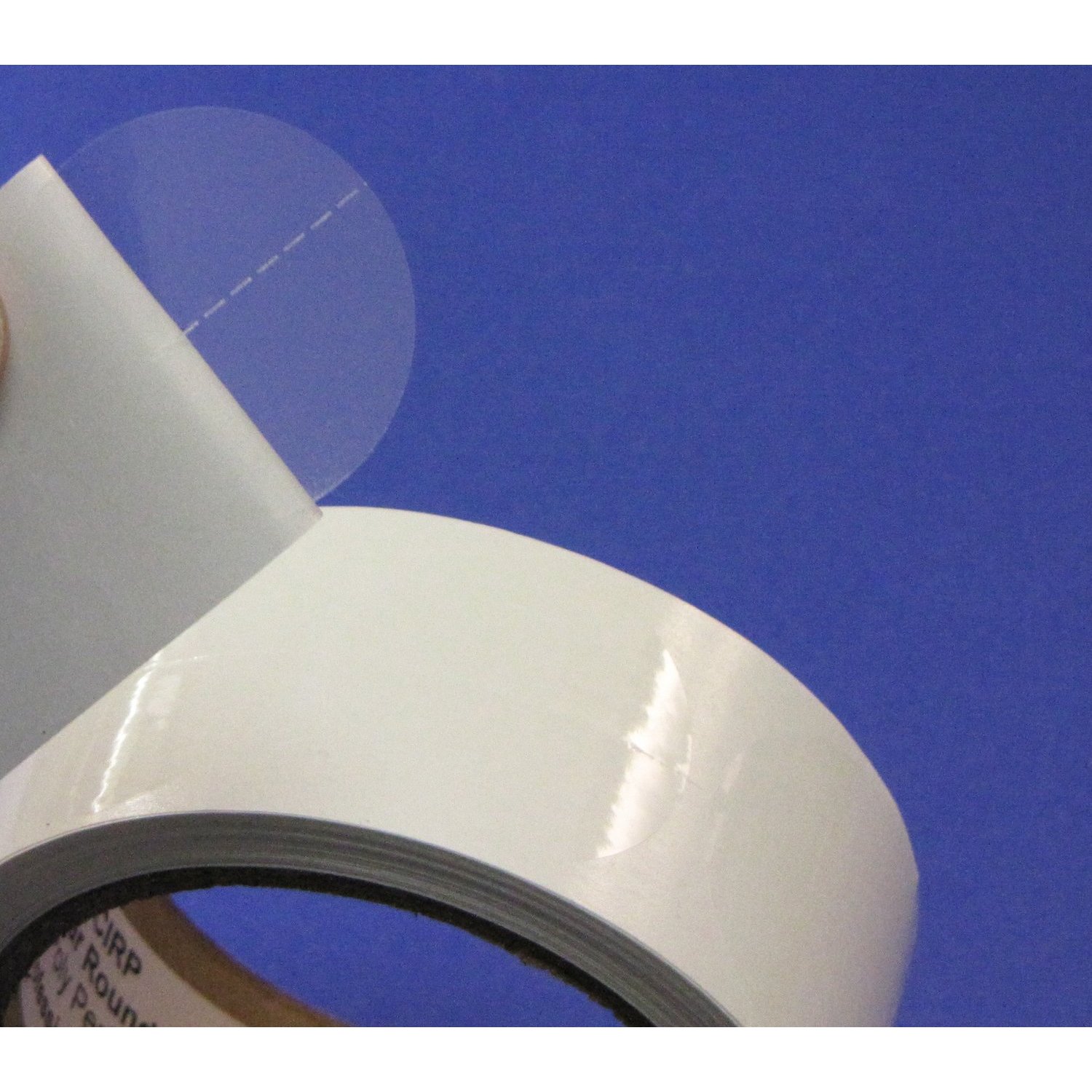

These perforated label seals are manufactured on rolls of 500 labels each, and they can be applied by machine or hand applied. They are compatible with the label dispenser #PL9500 which manually delivers the labels seals to your fingertips.

Perforated label seals can be used to seal almost any retail packaging, from cosmetics to perfume to electronic components to pharmaceutical and health care products, where the object is to seal, but make it easy for the end user to open without difficulty.

These are our popular 2 mil polypropylene clear label seals with Standard Permanent Adhesive and one center perforation:

The one inch clear label (1") 2 Mil is used mostly for sealing sleeves and small retail product packages and boxes. Also available with a center perforation.

The one and a half inch clear label (1 1/2") 2 Mil is used for sealing and small retail product packages and boxes. Item #15CIRP shown above has a center perforation.

If you are looking for mailing seals, please note that USPS postal regulations now call for label seals that are not perforated and the size must be 1.5 inches or 2 inches. For wafer tab seals that meet postal service regulations please see our mailing wafer selection below.

Mailing Wafer Seals

One and a Half Inch (1 1/2") and Two Inch (2") Paper Mailing Seals for Brochures and Magazines

The second type we will report on is the widely used Clear Translucent Label, also known as Clear Wafer Tab Seals. These are always on rolls, as they can be applied by machine or hand applied. Their primary application is mailing seals for mailing brochures, booklets and magazines. The United States Postal Service issued new guidelines and specifications recently that have changed significantly from past USPS requirements. They now require a minimum clear round (or white round label) that is 1 1/2 inches in diameter. The most popular one used is the clear translucent or frosted sealing label as it lets the graphic or package design show through. Perforated labels, which used to be the predominantly used label seal are no longer allowed due to their propensity to come apart in the mail sorting machinery and slow down the mailing process. Now the labels must be non-perforated.

Shown above are the new 1.5 inch clear frosted translucent labels that meet the new USPS regulations for mailing seals. When applied they become more clear enabling the text or graphics to show through.

1.5 inch clear translucent paper labels on a roll. Standard adhesive. The roll is on a 3" (three inch) core.

The USPS has also designated 2 inch (2") diameter paper label seals as the appropriate size to be used on heavier mailing pieces.

White Round Wafer Seals also

Available:

1.5"

white round mailing seals meet the new postal regulations for sealing

standard size and weight brochures and magazines. Easy to tear as per USPS regulations,

with no perforations.

Similar to 910416.

Shown above are the new 2 inch white paper labels that meet the new USPS regulations for mailing seals on larger, heavier mailing pieces such as magazines, catalogs, or booklets.

The postal service announced that to improve the productivity of processing

booklets and to decrease damage to mail pieces, the new standards require that

booklets have three separate, 1.5" tabs on the sides of the mail piece. Also,

tabs used to seal booklets may not be perforated to minimize tab failure. Tabs

with perforations are easily broken, do not maintain their integrity, and are

frequently damaged in transport prior to entering the mail stream.

The new specific USPS regulations for Booklets are listed below:

Booklets must have a bound edge (spine.) Sheets that are fastened with at least two staples in the manufacturing fold (saddle stitched), perfect bound, pressed-glued, or joined together by another binding method that produces a spine where pages are attached together are considered booklets. Booklets are open on three sides before sealing, similar in design to a book. In general, booklets must be uniformly thick. Large bound booklets that are folded for mailing may qualify for automation and machinable prices if the final mailpiece remains nearly uniform in thickness and conforms to all other automation standards.

Booklet covers generally must be made with a minimum paper basis weight of 60-pounds or equivalent. Minimum basis weights are higher for some designs (see 3.15.4).

a. Height: not more than 6 inches or less than 3.5 inches high.

b. Length: not more than 10.5 inches or less than 5 inches long. See Exhibit 3.15.5 through Exhibit 3.15.8 for some booklet designs with shorter maximum lengths.

c. Thickness: not more than 0.25 inch or less than 0.009 inch thick.

d. Weight: not more than 3 ounces.

e. Aspect ratio: within 1.3 to 2.5 (see 3.7).

The position of the final fold and intermediate fold (or spine) for letter-sized booklets varies according to the specific design of the mailpiece. Open edges can be sealed with tabs, glue lines, or glue spots. Except for the simple spine wallet-style design with a height of 4 inches and a maximum length of 8 inches; tabs used as seals on the leading edge of small booklets less than 5 inches high, may be placed closer to the top and bottom edges than shown in Exhibit 3.15.5 through Exhibit 3.15.8 and may overlap in some cases. See Exhibit 3.15.5 through Exhibit 3.15.8 for design and sealing standards by type of design.

The spine forms the bottom edge of the mailpiece. The length or method used to seal the booklet determines the weight of the paper forming the cover.

Exhibit 3.15.5 Simple Spine Booklets

|

Maximum length—9.5 inches unless noted Cover paper weight—80-pound paper unless noted: see Exhibit 3.2 |

|

|---|---|

|

5" to 9" long at least 50-pound paper Over 9" up to 10.5" at least 60-pound paper The front cover may be up to a maximum of 0.25" shorter than pages and rear cover. Place one tab on the leading and trailing edges within 1" from the top; position one tab on the lower leading edge 0.5" from the bottom. |

|

|

Extended front folded over enclosed pages to create a nonperforated inner flap. Flap sealed inside of back cover. Seal with a continuous glue line along flap as described in 3.11g (preferred), or 1-inch glue spots as described in 3.11f. |

|

|

Cover extends no more than 5/8 inch beyond inner pages. Seal with a continuous glue line along extended cover as described in 3.11g (preferred), or with 1-inch glue spots as described in 3.11f. |

|

|

Lightweight Simple Spine Booklets Cover paper weight—70-pound paper unless noted: see Exhibit 3.2 |

|

|

Cover extends no more than 5/8 inch beyond inner pages. Seal with a continuous glue line as described in 3.11h. |

|

|

Addressed side of the cover extends over all pages on the back to create a flap. Flap length: at least 1.5" wide when measured down from the top edge. May be longer, but cannot be closer than 1-inch from bottom edge. Flap attaches to the outside of the nonaddressed side of the cover. Seal with a continuous glue line as described in 3.11h. |

|

|

Addressed side of the cover extends over internal pages to create an inside flap. Flap length: at least 1.5" wide when measured down from the top edge. Flap attaches to the inside of the nonaddressed side of the cover. Seal with a continuous glue line as described in 3.11h. |

|

|

Mid-Weight Simple Spine Booklets Weight—over 0.8 ounce up to 1.6 ounces Cover paper weight—70-pound paper unless noted: see Exhibit 3.2 |

|

|

Cover extends no more than 5/8 inch beyond inner pages. Seal with a continuous glue line as described in 3.11h, and one nonperforated tab 0.5 inch from the bottom leading edge. Minimum tab size: 1.5 inches. |

|

|

Addressed side of the cover extends over all pages on the back to create a flap. Flap length: at least 1.5" wide when measured down from the top edge. May be longer, but cannot be closer than 1-inch from bottom edge. Flap attaches to the outside of the nonaddressed side of the cover. Seal with a continuous glue line as described in 3.11h, and one nonperforated tab 0.5 inch from the bottom leading edge. Minimum tab size: 1.5 inches. |

|

|

Addressed side of the cover extends over internal pages to create a flap. Flap length: at least 1.5" wide when measured down from the top edge. Flap attaches to the inside of the non-addressed side of the cover. Seal with a continuous glue line as described in 3.11h, and one nonperforated tab 0.5 inch from the bottom leading edge. Minimum tab size: 1.5 inches. |

|

|

Heavy weight simple spine booklets Weight—over 1.6 ounces up to 3 ounces Cover paper weight—70-pound paper unless otherwise noted: see Exhibit 3.2 |

|

|

Cover extends no more than 5/8 inch beyond inner pages. Seal with a continuous glue line as described in 3.11h and two 1.5" nonperforated tabs. One tab placed on the leading edge 0.5 inches from bottom and one tab placed 1-inch from top leading edge. |

|

|

Addressed side of the cover extends over all pages on the back to create a flap. Flap length: at least 1.5" wide when measured down from the top edge. May be longer, but cannot be closer than 1 inch from bottom edge. Flap attaches to the outside of the nonaddressed side of the cover. Seal with a continuous glue line as described in 3.11h and two 1.5" nonperforated tabs. One tab placed on the leading edge 0.5 inches from bottom and one tab placed 1-inch from top leading edge. |

|

|

Addressed side of the cover extends over internal pages to create a flap. Minimum flap length: at least 1.5" wide when measured down from the top edge. Flap attaches to the inside of the non-addressed side of the cover. Seal with a continuous glue line as described in 3.11h and two 1.5" nonperforated tabs. One tab placed on the leading edge 0.5 inches from bottom and one tab placed 1-inch from top leading edge. |

|

A spine forms the bottom edge. Wallet style booklets must be from 5.2 inches to 8 inches long, 4 inches high; can weigh up to 2.5 ounces; and must be sealed with nonperforated tabs. Tab size and placement are dictated by the weight of the booklet.

Exhibit 3.15.6 Wallet Style Booklets

|

Maximum length—5.2 to 8 inches Cover paper weight—70-pound paper unless otherwise noted: see Exhibit 3.2 |

|

|---|---|

|

Entire booklet 60-pound paper, OR Cover 70-pound paper, inner pages 50-pound paper. Booklets up to 2 ounces: sealed with 1.5" nonperforated tabs placed 1-1/4" from bottom leading and trailing edge. Over 2 ounces: use 2" nonperforated tabs placed 3/4" from bottom leading and trailing edge. |

|

Oblong booklets have a spine on the leading (shorter) edge.

Exhibit 3.15.7 Oblong Booklets

|

Cover paper weight—70-pound paper unless otherwise noted: see Exhibit 3.2 |

|

|---|---|

|

Over 9" up to 10.5": 70-pound paper Place two 1.5" nonperforated tabs on the top edge and one tab on trailing edge. Position top tabs 1-inch from left and right edges. Position one 1.5" nonperforated tab in the middle of the trailing edge. |

|

|

Over 9" up to 10.5" 70-pound paper The front OR back cover sheet is extended on the trailing edge and folded over the non-recessed internal pages. The flap is sealed inside the opposite cover sheet with glue. Extended front and back covers are not allowed with glue line seals. Seal with a continuous glue line as described in 3.11h. Place two 1.5" nonperforated tabs on the top edge 1-inch from the leading and trailing edges. |

|

Folded booklets are mailpieces that are bound and then folded to letter-size. The folded spine may be the leading edge or at the top of the booklet. If necessary, the booklet may be prepared with the spine as the trailing edge, however, this configuration is not recommended. The cover is at least 40-pound paper. Folded booklets must be sealed with nonperforated 1.5" tabs.

Exhibit 3.15.8 Folded Booklets